The Need for Propane Compressor in Efficient Industrial Operations

What is meant by a propane compressor?

With a propane compressor, propane gas may be compressed from lower to greater pressure. A flammable hydrocarbon gas known as propane is frequently utilized as a fuel for various purposes, including industrial activities and transportation.

Why Are Propane Compressors Important for Effective Industrial Operations?

Due to their capability to handle and transport propane gas effectively, propane compressors are essential in many industrial processes. Liquefied petroleum gas (LPG), often known as propane, is a flexible and clean-burning fuel used in various industrial operations, including heating, power production, manufacturing, and more. Propane compressor is necessary for effective industrial operations for the following reasons:

Gas transportation and storage effectiveness:

Because propane is more portable and manageable in this form, it is frequently transported and stored as a liquid under pressure. The volume of propane is greatly reduced when it is pressurized to turn it from a gas into a liquid. Then, with the aid of pipes, cylinders, and tanks, this compressed liquid propane may be transported or stored effectively while taking up less room.

Increased Energy Density:

Propane’s energy density rises due to compression, allowing for more energy storage in a given amount of space. Applications with limited area, such as those at outlying industrial sites or transportation, can benefit especially from this.

Power generating:

In distant locations or as a backup power source, propane is frequently employed as a fuel for power generation. Propane-powered generators are often employed in industrial buildings, hospitals, data centers, and other crucial infrastructure. Propane compressors make electricity production possible, providing a steady supply of pressurized propane to these generators.

Manufacturing Processes:

Numerous production procedures call for precise temperature control, which is easily accomplished with equipment fuelled by propane. By supplying industrial furnaces, ovens, and other equipment with pressurized propane, propane compressors provide constant and regulated heat levels for various manufacturing processes.

Fuel That Burns Cleaner:

When compared to other fossil fuels, propane is thought to burn cleaner. It is a more eco-friendly solution for industrial operations since it burns with less particulate matter and greenhouse gas emissions. Propane compressors make efficient use of this cleaner fuel source possible, in line with sustainability objectives.

Versatility:

In addition to being used in industry and power generation, propane has many other uses. It serves as fuel for vehicles, heating rooms, and water. Propane compressors assist these various applications by supplying numerous end-use devices with a consistent flow of compressed propane.

Remote Operations:

Propane can be a practical choice in remote locations where access to conventional energy sources may be difficult. Propane compressors make it possible to store and deliver propane to these outlying areas, facilitating industrial activity that problems with energy accessibility would otherwise hamper.

Cost-Effectiveness:

Propane is frequently more affordable than other fuels, and its effective use of compressors for storage and transportation results in cost savings in industrial processes. This is crucial for companies looking to minimize their operational costs.

The Powerhouse of Efficiency: Unleashing Propane Compressor’s Potential:

Propane compressor stands out as a true powerhouse in industrial operations, where energy effectiveness, dependability, and adaptability are crucial. The potential of propane, a flexible and clean-burning fuel, to drive effective operations across several industries depends critically on these technical wonders. Propane is compressed utilizing these inventive devices to create an extremely compact liquid state, which may be used as energy storage. This alteration greatly lowers its volume, enabling effective transit and storage. Thanks to propane compressors, industries can store higher amounts of energy in constrained locations, assuring a steady supply for crucial activities.

- Accurate temperature control and reliable energy sources are frequently needed for industrial operations. Compressor-driven propane-powered machinery offers a dependable energy supply. The regulated release of compressed propane, which provides constant heat levels, improves the quality and dependability of manufacturing, power generation, and heating operations.

- As the globe moves toward sustainability, propane is becoming more environmentally friendly than other fuels. Fewer pollutants and greenhouse gases are released during the combustion of compressed propane. This perfectly complements environmental objectives and enables businesses to lessen their carbon footprints and help the environment.

- Compressor-driven propane generators provide a reliable fallback during power outages. This is significant for vital institutions like hospitals, data centers, and industrial plants, where a steady supply of energy is essential.

- Compressors can use propane completely, positioning it as a vital participant in the transition to future energy sustainability. Propane is a crucial component of the energy mix due to its efficiency and compatibility with renewable energy sources.

Where Can You Find an Excellent propane compressor?

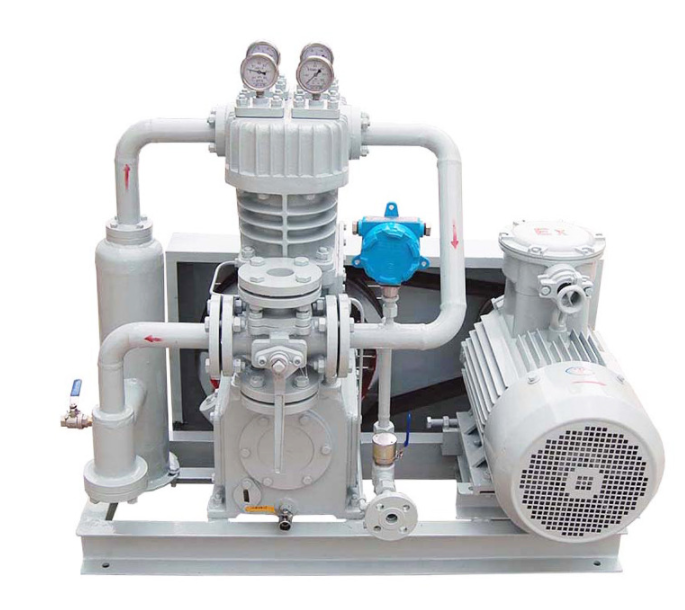

With their expert technical design, performance calculation, machining, welding, assembly, testing, and other manufacturing and processing abilities, HUAYAN can develop high-quality propane compressor. Additionally, we have access to several cutting-edge processing tools. For more than 40 years, we have been active in the propane industry. The compressor was designed with process flow in mind. The entire machine is skid-mounted and has an excellent sealing system and innovative design. HUAYAN is regarded as a top provider of propane *compressors; their reputation for creating top-notch goods has grown within the market. It’s crucial to choose suppliers for commercial machinery like propane compressors and to analyze their reputation, client feedback, product specs, and after-sales service.

Conclusion:

A propane compressor is necessary for effective industrial operations because they make the transportation, storage, and use of propane gas easier. Our compressors play a crucial role in raising productivity, dependability, and sustainability in several sectors by boosting energy density, maintaining a consistent supply, and supporting various applications. HUAYAN can provide any client globally with full one-stop solutions, and we promise that every customer will receive high-quality products and outstanding customer service. Methane, ethane, carbon three, carbon four, and other gases comprise most of the gas’s constituents. Water, hydrogen sulfide, and other gases are also mixed in.