Process gas compressor

A diaphragm compressor is a variant of the classic reciprocating compressor with backup and piston rings and rod seal. The compression of gas occurs by means of a flexible membrane, instead of an intake element. The back and forth moving membrane is driven by a rod and a crankshaft mechanism.

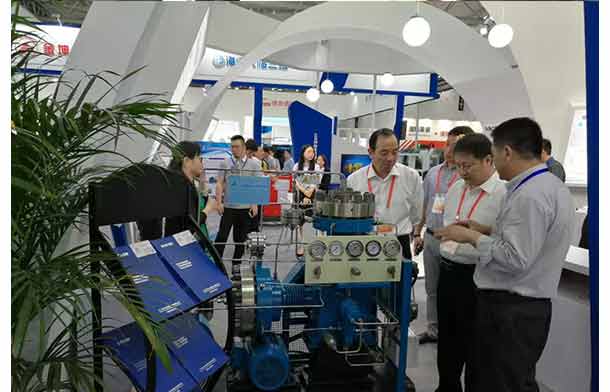

Products show

Committed to Manufacturing Solutions

Process gas compressors refer to reciprocating piston compressors used to compress various single or mixed medium gases in petroleum, chemical and other process processes. In the process of petroleum, chemical, gas industry, etc., it is often necessary to provide a strict physical environment to support the process. As the core dynamic equipment in the process device, the reciprocating compressor of the process is mainly used to transport the medium to the reverse device. Gas, and provide the required pressure to the reaction device. The process compressor produced by our company has nearly a thousand products, which can compress various media, such as coal gas, biogas, hydrogen gas, natural gas, fluorine chemical gas, tail gas, alkanes, olefins, ingredient gas, non-condensable gas, associated gas, Raw gas, analytical gas, carbon monoxide, carbon dioxide, ammonia, hydrogen, liquefied petroleum gas, helium, argon, etc.

We can provide to...

- Turn times as short as 24 hours

- 1 to 100,0 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- Ce Certification

-

Program Design

-

Technical Characteristics

-

REOUIREMENTS FOR COMPRESSOR INQUIRY

-

Equipment Exhibition

Our compressors serve many countries in Asia, America, Africa, Europe, Australia, etc.We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

Technical Characteristics

| Power | 7.5-250kw |

| Voltage | 380V 3phase |

| Working Pressure | 7-13bar |

| Flow | 1m³-38m³/min |

| Start Method | Frequency Conversion Start |

| Cooling Method | From HYWV-7G to HYWV-45G Airing cooling HYWV-55G to HYWV-250G Water cooling |

| Material | Stainless Steel |

| Deliver Time | 1 samples Within 3days |

WHEN A CUSTOMER ORDERS A COMPRESSOR OR AN INQUIRY, THE FOLLOWING BASIC PARAMETERS SHOULD BE PROVIDED

| SUCTION PRESSURE MPa(G) | DISCHARGE PRESSURE MPa(G) |

| VOLUME FLOW (NM3/H) |

| SUCTION TEMPERATURE ℃ | DISCHARGE TEMPRETURE ℃ |

| DISCHARGE TEMPRETURE AFTER COOLING ℃ |

Gas Compressor Technology Solutions

- Technical engineers have 30 years of experience in gas compressor design

- The factory area is 91260m2, with more than 50 skilled workers and more than 15 design engineers

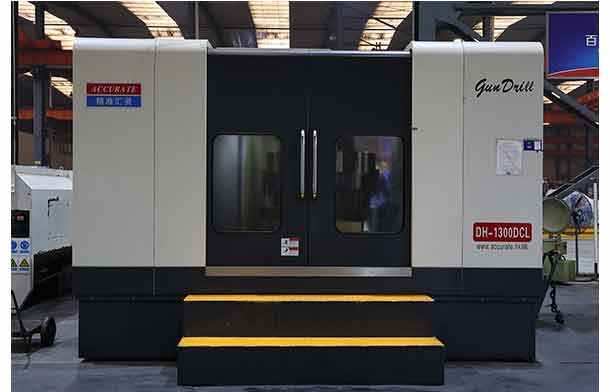

- Own CNC machining center, milling machine, welding, inspection, assembly, testing, storage and other complete production lines.

- Manufacture of inert, flammable, explosive, corrosive and toxic gas compressors

- Professional compressor after-sales service team can provide technical support abroad

- Member of China General Machinery Compressor Industry Association

- Holder of ISO9001, ISO14000, patented technology, EU CE certificate.

- We can better meet the needs of customers and provide cost-competitive products.

Bring you better products

30 years of compressor design & manufacturing experience

High Frequency asked questions

What is your MOQ?

Are you a factory?

What do I need to do if I want to get proposals and quotes?

Warranty terms of your machine?

Which payment term can you accept?

Can you accept OEM orders?

Why Choose Us?

We have a deep understanding of the needs and requirements of the compressor industry, and we are striving to become a leader in this field.

-

Factory area: 91260m2

-

Technical engineer work experience: 30 years +

-

Exporting countries: 99+

-

Customer Satisfaction: 100%

-

Invention and utility patents: 20+