Unleashing the Power of Hydrogen with a Diaphragm Compressor

Hydrogen, often hailed as the fuel of the future, has the potential to revolutionize the way we power our world while reducing our carbon footprint. But what’s the secret behind harnessing the power of hydrogen effectively? One crucial piece of the puzzle is the hydrogen diaphragm compressor. In this article, I’ll guide you through the world of hydrogen diaphragm compressors, from their uses and benefits to a step-by-step guide on how they work. We’ll also address some common questions and provide a conclusion to help you grasp the importance of this technology.

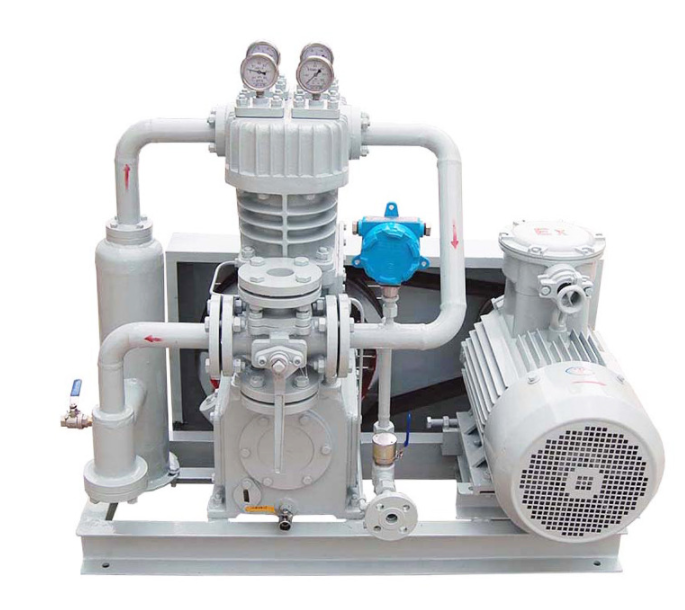

Understanding the Hydrogen Diaphragm Compressor

A hydrogen diaphragm compressor is a specialized type of compressor designed specifically for handling hydrogen gas. Compressors are crucial in various hydrogen-related applications, from refueling stations for hydrogen-powered vehicles to industrial processes and research facilities.

Why Hydrogen Compression Matters

Before we dive into the specifics of hydrogen diaphragm compressors, let’s explore why hydrogen compression is so important in the first place:

- Storage and Transportation: Hydrogen is a lightweight gas that requires compression for efficient storage and transportation. Compressed hydrogen occupies less space, making it practical for various applications.

- Refueling Stations: Hydrogen-powered vehicles rely on compressed hydrogen for refueling. Diaphragm compressors play a vital role in providing a reliable source of high-pressure hydrogen at refueling stations.

- Industrial Processes: Hydrogen is widely used in industrial processes, from chemical manufacturing to electronics production. Diaphragm compressors enable the compression of hydrogen for these applications.

Now that we’ve established the importance of hydrogen compression let’s explore the world of hydrogen diaphragm compressors.

Advantages of Using Hydrogen Diaphragm Compressors

Hydrogen diaphragm compressors offer several advantages:

1. Safety

Safety is paramount when working with hydrogen due to its flammability. Hydrogen diaphragm compressors are inherently safe because they are oil-free and have no lubricated parts that could pose a risk.

2. Purity

Maintaining the purity of compressed hydrogen is crucial in many applications, such as electronics and semiconductor manufacturing. Hydrogen diaphragm compressors excel at preserving the purity of the gas.

3. Leak-Free

Diaphragm compressors are known for their minimal gas leakage, ensuring efficient compression and minimal hydrogen loss.

4. Versatility

These compressors can handle a wide range of hydrogen pressures, making them suitable for various applications, from low-pressure storage to high-pressure refueling.

Now that we understand the advantages, let’s move on to a step-by-step guide on how hydrogen diaphragm compressors work.

How Hydrogen Diaphragm Compressors Work

Understanding the operation of hydrogen diaphragm compressors is essential for appreciating their significance in hydrogen-related applications. Here’s a simplified step-by-step explanation:

Step 1: Inlet Phase

- Hydrogen gas enters the compressor through an inlet valve.

- The compressor contains two flexible diaphragms—one on the suction side and one on the discharge side.

Step 2: Suction Phase

- During the suction phase, the suction diaphragm expands, creating a vacuum chamber.

- As the diaphragm expands, it draws in hydrogen gas from the inlet.

Step 3: Compression Phase

- Once the vacuum chamber is filled with hydrogen gas, the suction diaphragm begins to compress.

- As the diaphragm compresses, it reduces the volume of the gas, increasing its pressure.

Step 4: Discharge Phase

- The compressed hydrogen gas is then expelled through the discharge valve.

- The discharge diaphragm expands to allow the gas to exit, maintaining a continuous flow.

Step 5: Repeat

- The cycle repeats, creating a continuous flow of compressed hydrogen gas.

Hydrogen diaphragm compressors are known for their ability to provide a consistent and controlled source of high-pressure hydrogen, making them invaluable in various applications.

FAQs About Hydrogen Diaphragm Compressors

Here are some frequently asked questions about hydrogen diaphragm compressors:

Q1: Are hydrogen diaphragm compressors suitable for hydrogen refueling stations?

A1: Yes, hydrogen diaphragm compressors play a crucial role in hydrogen refueling stations, providing the high-pressure hydrogen needed for fueling hydrogen-powered vehicles.

Q2: Do hydrogen diaphragm compressors require maintenance?

A2: Like all equipment, hydrogen diaphragm compressors require regular maintenance to ensure optimal performance. This may include inspections, diaphragm replacements, and lubrication of moving parts.

Q3: Can hydrogen diaphragm compressors be used for other gases besides hydrogen?

A3: Hydrogen diaphragm compressors are versatile and can be adapted for compressing various gases, depending on the design and materials used.

Q4: Are hydrogen diaphragm compressors energy-efficient?

A4: Hydrogen diaphragm compressors are known for their energy efficiency, consuming less energy compared to some other types of compressors. Their oil-free design also reduces maintenance costs.

Q5: What safety measures should be taken when working with hydrogen diaphragm compressors?

A5: Safety measures include ensuring proper ventilation to disperse any potential hydrogen leaks and following industry-specific safety guidelines when handling compressed hydrogen.

Conclusion

Hydrogen diaphragm compressors are unsung heroes in the world of hydrogen technology, enabling the safe and efficient compression of hydrogen gas for a wide range of applications. Their inherent safety, purity preservation, minimal gas leakage, and versatility make them indispensable tools in industries where hydrogen plays a significant role. As we continue to explore the potential of hydrogen as a clean and renewable energy source, hydrogen diaphragm compressors will undoubtedly continue to play a crucial role in shaping our sustainable future. So, the next time you come across hydrogen-powered technology, remember the unsung hero—the hydrogen diaphragm compressor—that makes it all possible.