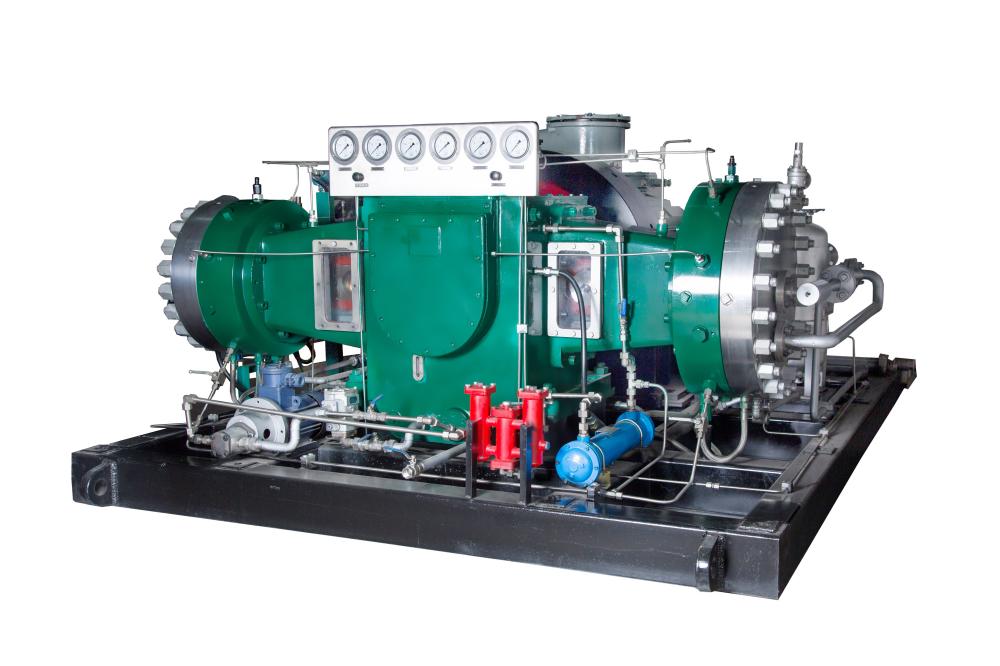

The power behind High pressure oxygen compressor

What is meant by High pressure oxygen compressor?

A special kind of compressor made to compress oxygen gas to high pressures is a high pressure oxygen compressor. Since these compressors can produce compressed oxygen at pressures greater than atmospheric pressure, the name “high pressure” denotes this capability. In general, oxygen compressors take in ambient air or oxygen that has already been treated and compress it via a number of compression stages to a higher pressure. In different applications requiring high-pressure oxygen, the high-pressure compressor specializes in compressing oxygen gas.

- These compressors are specifically designed to handle oxygen gas’s special characteristics and demands. To assure safety and eliminate any chance of combustion or other risks connected with oxygen-rich settings, they frequently integrate specific materials and components that are compatible with oxygen.

- In fields including healthcare, aerospace, diving, and industrial operations, high-pressure oxygen compressors are essential where a dependable and regulated supply of compressed oxygen at high pressures is required. They are essential in providing oxygen for medical procedures, pressuring aeroplane cabins, scuba diving, and industrial activities requiring oxygen.

The function of High pressure oxygen compressor:

For various applications, oxygen gas is compressed to a higher-pressure level using a high pressure oxygen compressor. It is essential to many fields, including industrial operations, diving, aircraft, and healthcare. The role and significance of a high-pressure oxygen compressor are as follows:

Function:

- Compression:

A high-pressure oxygen compressor’s job is to increase the pressure of outside air or air enhanced with oxygen. Typically, it draws air or oxygen already treated from the atmosphere and builds pressure through a series of compression steps.

- Filtering:

Oxygen compressors frequently include filtering systems to remove pollutants, moisture, and contaminants from the incoming air or oxygen. By doing this, it is made sure that the compressed oxygen is of the highest quality and appropriate for the intended use.

- Cooling:

High-pressure oxygen compressors have cooling devices to keep the temperature within tolerable ranges since compression produces heat. Intercoolers, aftercoolers, or heat exchangers may be used in cooling to remove the heat produced during compression.

- Safety features:

Oxygen compressors use safety mechanisms to guard against potential risks. These may include pressure release valves, temperature sensors, and other devices to ensure the compressor functions within safe parameters and guard against over-pressurization or overheating conditions.

What is the importance of High pressure oxygen compressor?

- Medical Applications:

They provide compressed oxygen for various therapeutic and life support devices, such as ventilators, anaesthesia machines, and oxygen concentrators. To address the demands of patients with respiratory problems, these devices depend on a continuous flow of high-pressure oxygen.

- Aerospace Industry:

Applications for compressed oxygen are found in the aerospace industry, including in space travel. It is crucial for giving pilots, crew, and passengers access to breathing air at high altitudes where oxygen levels are low. High-pressure oxygen compressors guarantee an adequate supply of compressed oxygen for oxygen masks, onboard systems, and cabin pressurization.

- Scuba diving:

To fill their diving tanks with compressed air or enhanced oxygen mixtures, scuba divers rely on high-pressure oxygen compressors. Divers can safely breathe underwater and explore further depths thanks to these compressors. They are essential to both commercial and recreational diving operations.

- Industrial Processes:

High pressure oxygen compressor is used in metallurgy, chemical manufacture, wastewater treatment, and oil refining, among other industrial processes. In these processes, oxygen is frequently employed as a feed gas, and compressing it to high pressures guarantees effective and regulated delivery to the necessary uses.

What are the advantages of High pressure oxygen compressor?

Compressors for high-pressure oxygen provide several advantages in various fields and uses. Some of the main benefits of employing high-pressure oxygen compressors are as follows:

- Reliable Supply of High-Pressure Oxygen:

These compressors make sure that there is a steady and reliable supply of compressed oxygen at high pressures. This is essential for operations used in industry, aerospace systems, and medical treatments that call for high-pressure oxygen. Thanks to the compressors, users can get the appropriate oxygen levels to satisfy their unique needs.

These compressors allow storing and transporting oxygen more effectively by compressing oxygen gas to greater pressures. As the same volume of oxygen can be held at greater pressures, it eliminates the requirement for large storage systems and frees up space. Additionally, greater pressure levels make it easier to deliver compressed oxygen to remote sites, maintaining a consistent supply in places where oxygen may be in short supply.

- Improved Performance in Medical Treatments:

These oxygen compressors are essential in medical settings and can improve treatment performance. They ensure that high-pressure oxygen is delivered to medical equipment that needs it, such as ventilators and oxygen concentrators. These devices can function well, offering the best respiratory support and enhancing patient outcomes since compressed oxygen is readily available at high pressures.

- Versatility in Industrial Processes:

These oxygen compressors are used in various industrial processes in the metallurgical, chemical, wastewater treatment, and oil refining industries. These procedures employ compressed oxygen at high pressures as feed gas to increase productivity, encourage combustion, or facilitate chemical reactions. The compressors provide adaptability and flexibility in delivering compressed oxygen to fulfil the unique needs of different industrial processes.

- Productivity and Efficiency Gains:

These compressors help industrial operations become more productive and efficient. These compressors provide faster and more precise oxygen delivery to the necessary applications by supplying compressed oxygen at high pressures. As a result, processes operate more effectively, reactions go faster, and oxygen is used more effectively in diverse industrial settings.

Conclusion:

For the effective and safe supply of oxygen in industrial and medical contexts, a high pressure oxygen compressor is crucial equipment. They are employed in several applications and are made to compress oxygen to extremely high pressures. HUAYAN International Trade is a trustworthy partner committed to offering top-notch products and top-notch service to satisfy various oxygen compression demands.