The Amazing Advantages of an Ammonia Synthesis Compressor

What does an ammonia synthesis compressor mean?

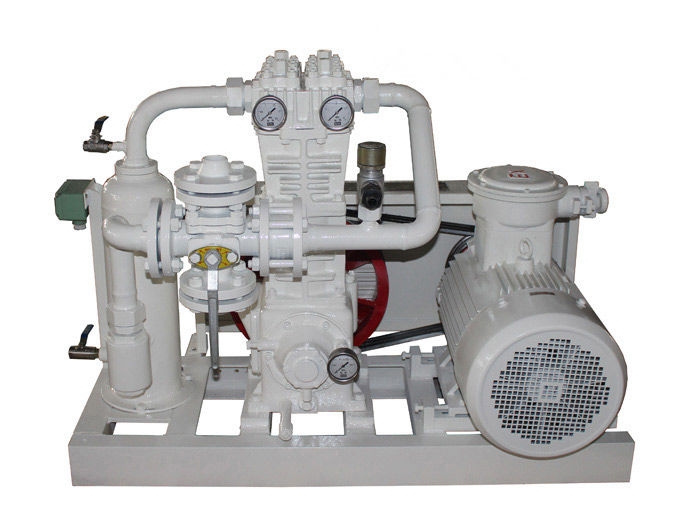

- The ammonia synthesis compressor refers to a particular compressor used to produce ammonia. The chemical process known as ammonia synthesis creates ammonia (NH3) from nitrogen (N2) and hydrogen (H2) gases. The ammonia synthesis compressor plays a critical part in this process by compressing the reactant gases (nitrogen and hydrogen) to high pressures before they reach the synthesis reactor. The compressor raises the gas pressure to the necessary amount for the ammonia synthesis process to occur effectively.

- Each stage of the compressor’s operation progressively raises the gas pressure. This is how most compressors work. Depending on the ammonia synthesis facility’s unique needs, it may employ various technologies, such as reciprocating compressors. By removing the reaction’s thermodynamic barriers by compressing the reactant gases, the ammonia synthesis compressor speeds up the production of ammonia molecules. The compressed gases are then introduced into the synthesis reactor, which reacts over a catalyst at high pressure and temperature to create ammonia.

A Crucial Part of Industrial Processes Is the Ammonia Synthesis Compressor:

The compressor used in ammonia synthesis is a crucial aspect of industrial operations, especially when producing ammonia. Among its many uses, are as fertilizers, refrigerants, and cleaning agents, ammonia is a significant chemical. To create ammonia, nitrogen and hydrogen gases must react at extreme pressure and temperature in the presence of a catalyst, usually iron or ruthenium. A compressor is attached to a series of reactors used to create ammonia. The compressor is essential throughout the operation in maintaining the necessary pressure levels. This is how it goes:

- Synthesis gas compression:

To create synthesis gas, hydrogen (H2) and nitrogen (N2) reactant gases are generally heated and combined before entering the compressor. The compressor then compresses the synthesis gas to a high pressure of up to 5,000 PSIG. The effective operation of the ammonia synthesis process depends on this high pressure.

- Removal of Reaction Heat:

Ammonia synthesis is an exothermic process, which means that heat is released. The temperature rises when the reactant gases are squeezed. To remove extra heat and maintain the proper temperature range for the reaction, the compressor often contains inter-stage coolers or heat exchangers.

- Catalyst Bed Pressure Maintenance:

After compression, the synthesis gas enters the catalyst bed within the reactors. The catalyst speeds up the process of turning hydrogen and nitrogen into ammonia. The compressor ensures that reactant gases flow continuously to maintain the pressure necessary for maximum catalyst activity.

- Recycling and Recompression:

Because the ammonia synthesis reaction isn’t entirely effective, some ammonia and unreacted gases escape the reactor. The compressor usually recycles these gases into the system, recompressed to the required pressure. This recycling aids in improving ammonia production and total reactant conversion.

The supplier of Gas Compressor Technology Solutions is HUAYAN:

There are more than 50 skilled employees and more than 15 design engineers working in the 91260m2 plant, which has technical engineers with 30 years of expertise in the design of gas compressors.

- It owns a milling machine, welding equipment, inspection equipment, testing equipment, storage equipment, and other comprehensive manufacturing lines.

- The manufacturing of gas compressors for poisonous, corrosive, flammable, and explosive gases

- Expert compressor after-sales service staff may offer technical assistance internationally.

- The Member of the China General Machinery Compressor Industry Association and holder of the ISO9001 and ISO14000 certifications and a patent and EU CE certification.

The Amazing Advantages of an Ammonia Synthesis Compressor:

Compressors used in ammonia synthesis are vital to creating ammonia, a substance utilized in several industries. These compressors have several outstanding advantages:

- Increased Production Efficiency:

The ammonia synthesis compressor helps to improve the overall efficiency of the ammonia generation process. These devices compress the ammonia gas created during the synthesis reaction, increasing its density and making it easier to separate from other reactants. This compression technique makes improved ammonia yields and greater production rates possible.

- Energy Optimization:

These compressors are designed to function at high pressures, allowing the ammonia gas to be compressed effectively. They aid in lowering operational costs and improving overall energy efficiency in ammonia manufacturing facilities by optimizing energy use.

- Enhanced Safety:

Because ammonia gas is harmful, the ammonia synthesis compressor is built with safety measures. They ensure compression is dependable and secure, reducing leaks and lowering the dangers of handling and processing ammonia. Safety features like pressure release and gas detection systems are built into the compressors for further security.

- Equipment Lifespan Extension:

The employment of ammonia synthesis compressors aids in extending the life of the industrial process’s machinery. These compressors prevent damage to other parts, including heat exchangers and catalyst beds, which are essential for ammonia synthesis by maintaining appropriate working conditions. This increases the equipment’s lifespan, lowers the need for maintenance, and minimizes downtime.

- Process Flexibility:

The operating parameters of the ammonia manufacturing process are flexible when using ammonia synthesis compressors. They can adapt to diverse feedstock compositions, enabling factories to efficiently process various feedstock types and change production in response to market needs. Ammonia compressors are useful in ammonia manufacturing facilities because of their versatility.

- Environmental Benefits:

Ammonia is frequently used in agriculture as a nitrogen-based fertilizer, which increases agricultural yields and positively affects the environment. The compressors indirectly aid in efficient food production and sustainable agriculture by boosting ammonia production. Additionally, the energy optimization made possible using these compressors helps lower the greenhouse gas emissions linked to manufacturing ammonia.

Conclusion:

Ammonia synthesis Compressor is utilized in industrial processes like fertilizer manufacturing and ammonia refrigeration systems. We offer the customer various advantages while facilitating efficient, economic ammonia production. It includes increased safety and environmental performance, decreased noise levels, and increased energy efficiency. HUAYAN can provide any client globally with full one-stop solutions, and we promise that every customer will receive high-quality products and outstanding customer service.